What Causes Control Arm to Brake?

It's important to understand the possible causes of control arm breakage and be aware of signs of wear and damage, so that necessary measures can be taken to avoid compromising safety on the road. When the control arm breaks, it can impact the vehicle's steering ability, leading to loss of control and posing a risk of accidents.

In this article, we will explore in detail the most common causes of control arm breakage, the signs to watch out for, and the preventive measures that drivers can take to minimize possible risks.

Structure of Control Arm

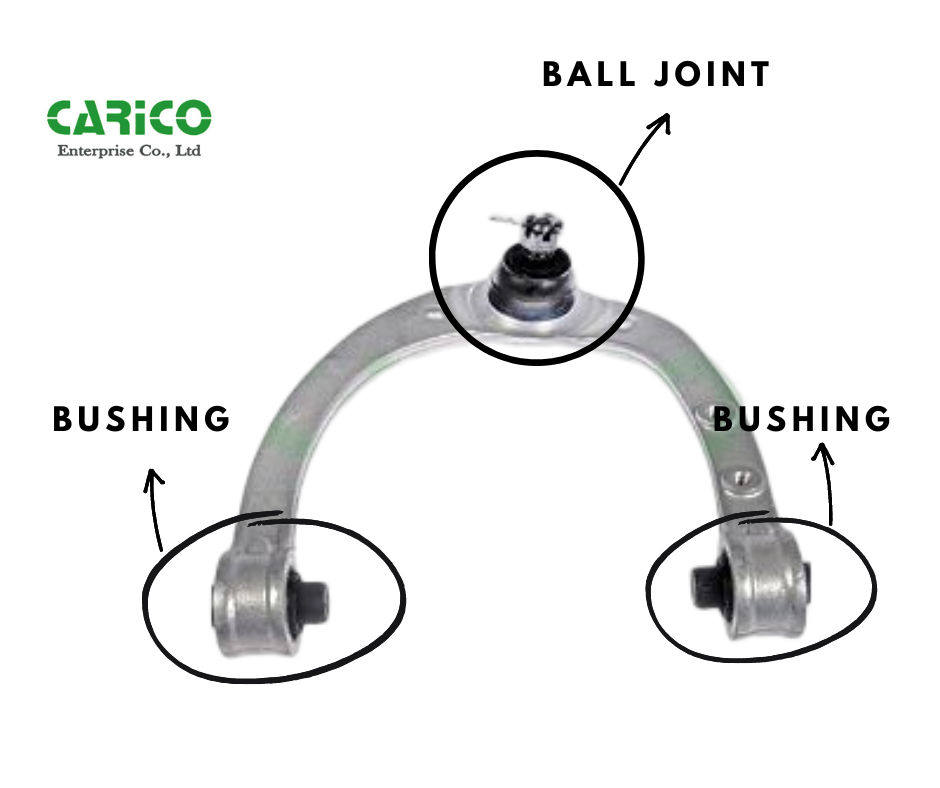

The control arm is an integral part of the suspension and steering system, although its exact structure may vary depending on the car's design. The typical components that make up the control arm are the upper and lower arms, ball joint, and bushings. In some cases, particularly in cars with independent front suspension, the control arm may connect to a stabilizer bar. Here is a description of each part of the control arm:

- Upper and lower arm: In an independent suspension system, the control arm is generally composed of an upper and a lower arm, as used in most modern cars. These arms are connected to the car's chassis or body at one end and to the suspension assembly at the other end.

- Ball joint and bushings: To allow movement and flexibility, the control arm has a ball joint and bushings at the connection points, which allow rotation and movement in multiple directions. Bushings are rubber or polyurethane components that act as bearings and reduce friction between the control arm and other suspension components.

How to tell if Control Arm is failing?

It is very important to recognize whether the control arm is broken or not to prevent danger while driving. Here are several signs that can be observed, the most common ones are:

#1 - Vibration in the steering wheel and diffculty turning

The reason for vibration in the steering wheel may be due to misaligned wheels that are vibrating due to excessive movement. Additionally, you may also experience difficulty turning or steering your car, particularly when taking turns, both signs may indicate a problem with the control arm.

#2 - Knocking sound and driving instability

If you hear a strange knocking or squeaking sound coming from the suspension or feel that your car is unstable while driving, especially when going over bumps or irregularities in the road, it is possible that the control arm is damaged.

#3 - Uneven tire wear

Uneven tire wear can reasonably be attributed to a broken control arm, especially on the outer edges. If you notice that your tires are wearing unevenly, you should be aware that there may be problems with the control arm.

Remember! the signs mentioned above can also be due to damaged ball joint or damaged bushing, both of which are attached to the control arm.

How to check if the Ball Joint is broken

How to replace Control Arm Ball Joint

ways to prevent from Control Arm Ball Joint breaking

Everything you should know about Bushing

The cause of the breakage of the Control Arm

The safety and performance of a car largely depend on a well-maintained suspension system, with one of its crucial components being the control arm, which plays a critical role in maintaining stability, control, and driving comfort. However, in some cases, the control arm may fail, which can have serious consequences for the safety of the car and its occupants. Let's take a look at the most common signs of control arm failure.

- Road conditions: Driving on poor road conditions, such as bumpy, uneven, or rough roads, can generate additional stress on the control arms. These conditions can cause excessive strain and premature wear, leading to control arm failure.

- Wear and aging: Over time, the control arm's materials can weaken and deteriorate gradually due to exposure to adverse environmental conditions, such as metal fatigue, moisture, or corrosion. The accumulated wear and aging of the parts can lead to the control arm becoming fragile and eventually breaking.

- Collisions and impacts: Control arms undergo great force while driving. If the car hits a large pothole, obstacle, or experiences a significant impact, the extreme load will likely damage or break the control arm. Both side and frontal impacts in traffic accidents can lead to control arm failure.

- Lack of maintenance: Inadequate maintenance, such as a lack of regular inspections or inadequate lubrication of pivot points, can accelerate the wear of control arms and increase the risk of failure.

- Manufacturing defects: In rare cases, there may be manufacturing defects in the control arms, such as poor welding, inappropriate designs, or defective materials. These factors can make the control arm more susceptible to failure, even under normal usage conditions.

Importance of the Control Arm

The control arm is crucial for the safety, performance, and comfort of a vehicle. It is used to control and limit the vertical movement of the wheels. This is essential for maintaining proper tire contact with the road surface, which provides stability and traction to the car. Additionally, the control arm plays an important role in the handling and stability of the car. It can absorb impacts and vibrations from the road like an additional shock absorber, resulting in a more comfortable driving experience for the driver and occupants. At the same time, it can keep the wheels aligned vertically and horizontally, which allows for better steering response, greater precision in turns, and overall safer driving. Ultimately, the control arm is designed to withstand significant loads and forces. It must be strong enough to withstand the stresses and strains generated while driving, particularly in situations such as acceleration, cornering, or sudden braking.

Funtion of control arm

► Minimize excessive bounce, lateral sway, and other unwanted suspension movements.

► Maintain the correct geometry of the suspension and keep the wheels aligned vertically and horizontally.

► Support enormous loads and forces.

► Ensure a smooth and stable ride.

►Contribute to the overall durability of the system.

A solid and well-built control arm ensures the reliability and durability of the car's suspension system. Control Arm - CARICO