How to Manufacture a Control Arm? - Carico

Normally, Control Arms are made from steel. The arms are manufactured by stamping separate details of the arm out of steel sheets and pressing them into their desired shape. The separate elements are welded together into a hollow arm, which is then painted. These are techniques that have been in use for more than a century. The necessary equipment for making components for the suspension of cars according to this method is in wide use, and the method is standard in all industrialized countries. Below is our manufacturing process for your reference.

Control Arm Manufacturing - Carico

The control arm is an important part of many mechanical systems including vehicles and heavy machinery. Control arm manufacturing consists of a series of steps, which can vary according to the specific design and requirements of the control arm in question.

Cutting-edge innovation

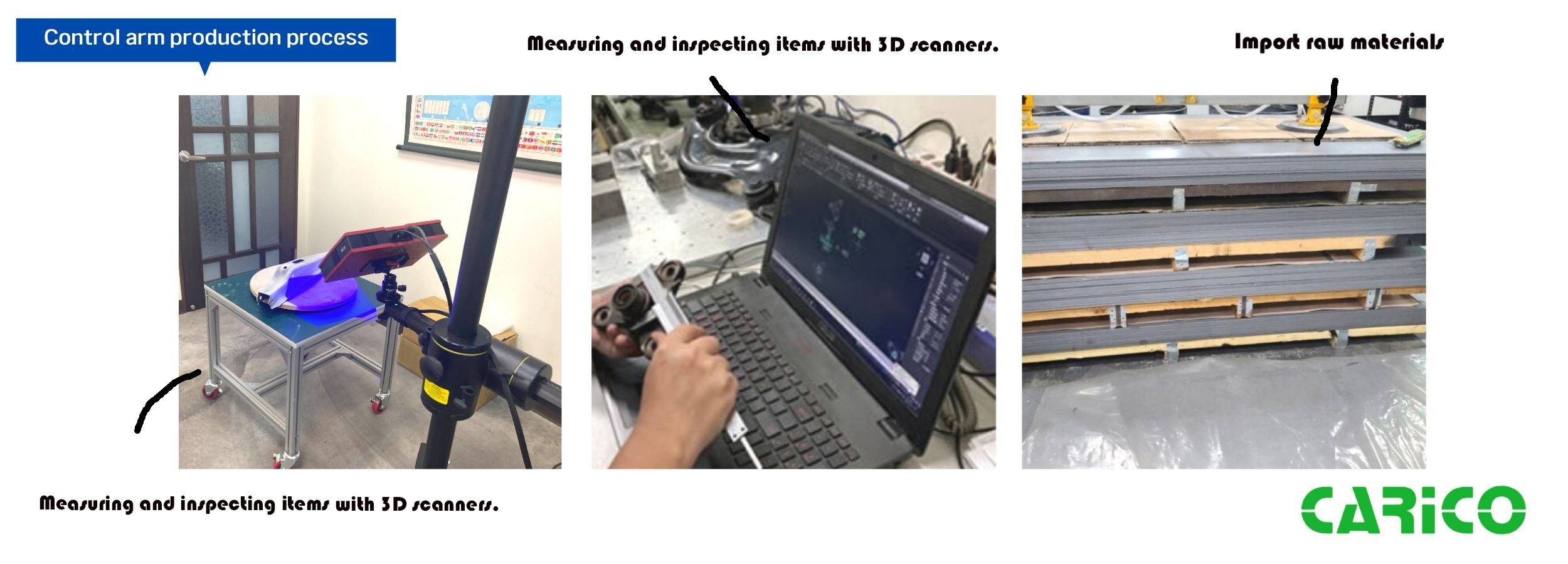

According to different product designs, we choose iron plate specifications, such as black iron plate, pickling plate, high tension plate, etc., and also match raw materials of various hardness and thickness due to different plates.

Strict test and manufacture

In response to changes in market demand and new models are being introduced, the procurement model has gradually changed to an increase in the number of models and a decrease in the number of single items.

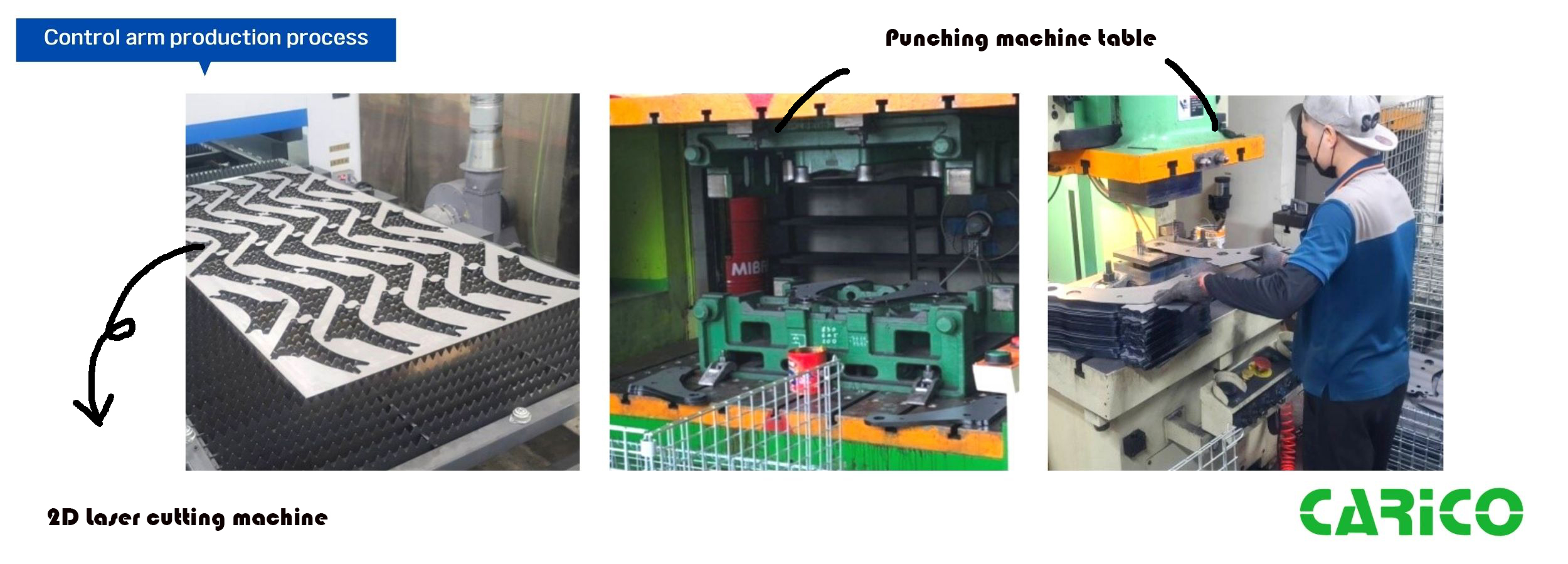

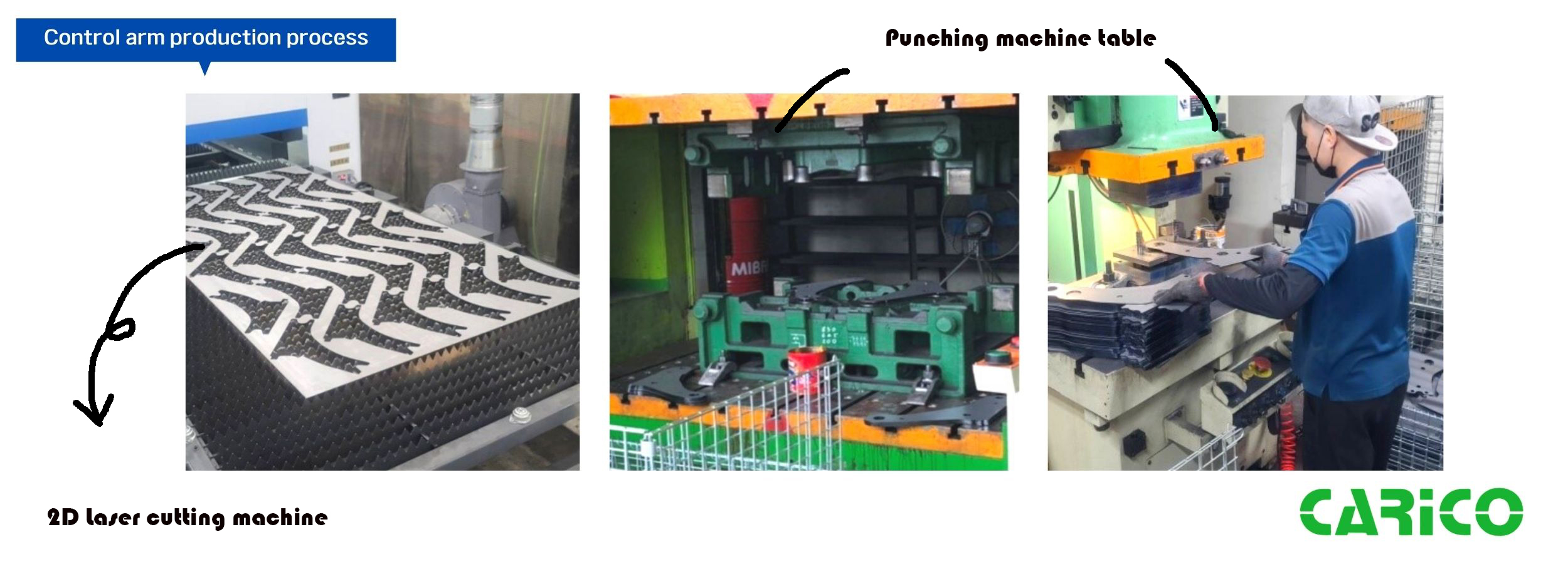

The traditional production method requires a large investment in mold costs, storage space and manpower. The automated 2D laser cutting machine can save manpower and can produce a variety of products at the same time, and can reduce errors and iron waves through computer typesetting calculations.

High quality assured and personalized service

The cut iron plate will be shaped for the pre-product. After placing the product mold on the punching machine table, the iron plate will be bent, flanged, sheared, etc. by the power of the equipment to make it conform to the various shapes and shapes of the mold.

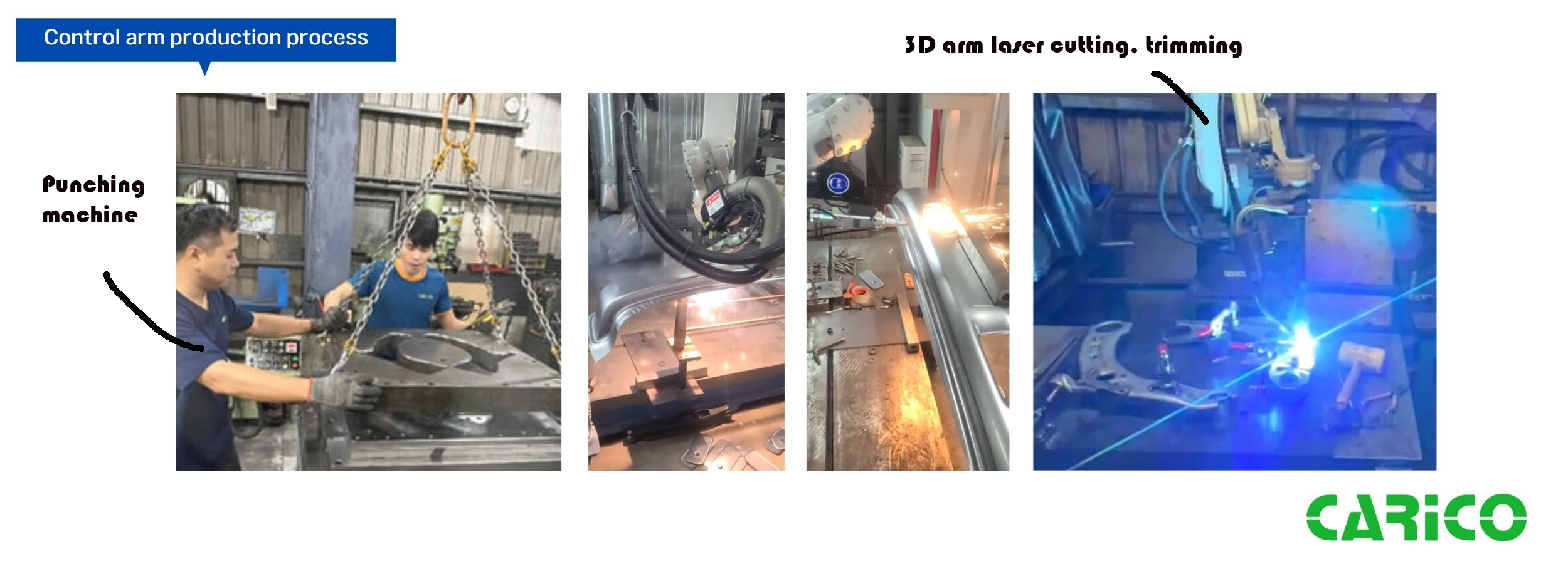

Because the metal workpiece will have a rebound deformation effect after the punching is completed, the angle and hole position of a small number of products cannot be set by the computer when the first punching is completed, so that the fine operation of the arm can achieve what we need. Product specifications also reduce the defective rate eliminated due to specification errors during manufacture, thereby reducing material loss.

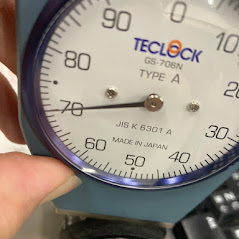

Normally our OEM parts from CARICO do according to the original factory standard, 70 shores. Position the lower control arm into a hydraulic press using a press cone and cup to force the bushing from the arm. Then, place the new bush into the control arm.

Development and dedication in control arm - Carico

Carico has spent a long time in control arm development, regardless of the complexity of the design, the amount of testing required and the experience of the development team, it has a high level of dedication to ensure the quality and success of the project.

In the design phase, Carico is fully committed to understanding the system requirements, identifying potential problems, and creating a detailed 3D model of the control arm. This can take weeks or even months, depending on the number of iterations and complexity in order to achieve a perfect model.

In the manufacturing phase, it must spend time to select the appropriate materials, prepare the manufacturing tools, and carry out the manufacturing process in detail with high precision and attention.

Finally, in the testing phase, Carico also should take mucho time to carry out extensive tests on the control arm to ensure that it fully meets the system requirements and is used safely. It may take a long time in the case of long-term fatigue testing.

More information↓

Clik here →The best Control Arm brands in the aftermarket

Contact CARICO today to find the Control Arm that you need!